How Jointing Operations make uPVC Windows more Eye-catchy?

Installing grade one windows in a home can be a lesser challenge if the right combination of accessories is applied while making them. The focus on having an appealing exterior is equally important to match the overall visage of the property. Modern uPVC window accessories suppliers are often contacted to help out.

OBEN is emerging as one of the leading uPVC window hardware manufacturers in India. They work alongside to offer the best products and options for fabricators and other vendors to improve the functionality of the windows.

This 5-minute post explains how a technical operation like jointing can make the entire window eye-catching. It will help our customers to explore more options for their prospective customers.

Understanding the Operations

A uPVC window / door is a thoroughly engineered product. The uPVC profiles are approximately 35% of the total material content in a window or a door. They come with the following components to form integral parts of the system:

- Steel Reinforcements (for insertion into the chambers of uPVC profiles for rigidity)

- Hardware (Metal fittings, Brush Seals, Gaskets, Plastic parts)

- Glass (as per customer requirement).

- Aluminium couplings to make combination windows like Casement + Sliding.

- Silicone sealant during window installation.

The Next Step

Main profiles of uPVC such as frame, mullion and sashes, are cut into required lengths & angles. It is followed by inserting steel reinforcements and welding. The recommended welding temperature for uPVC profiles is 250 degrees C + 10 depending on the compound formulation. Weld quality depends on heater plates maintaining the required temperature. The quality of Teflon cloth pasted on the heater plates is equally important. It is advisable to check the heater plate temperature on a daily basis before commencing the welding operation.

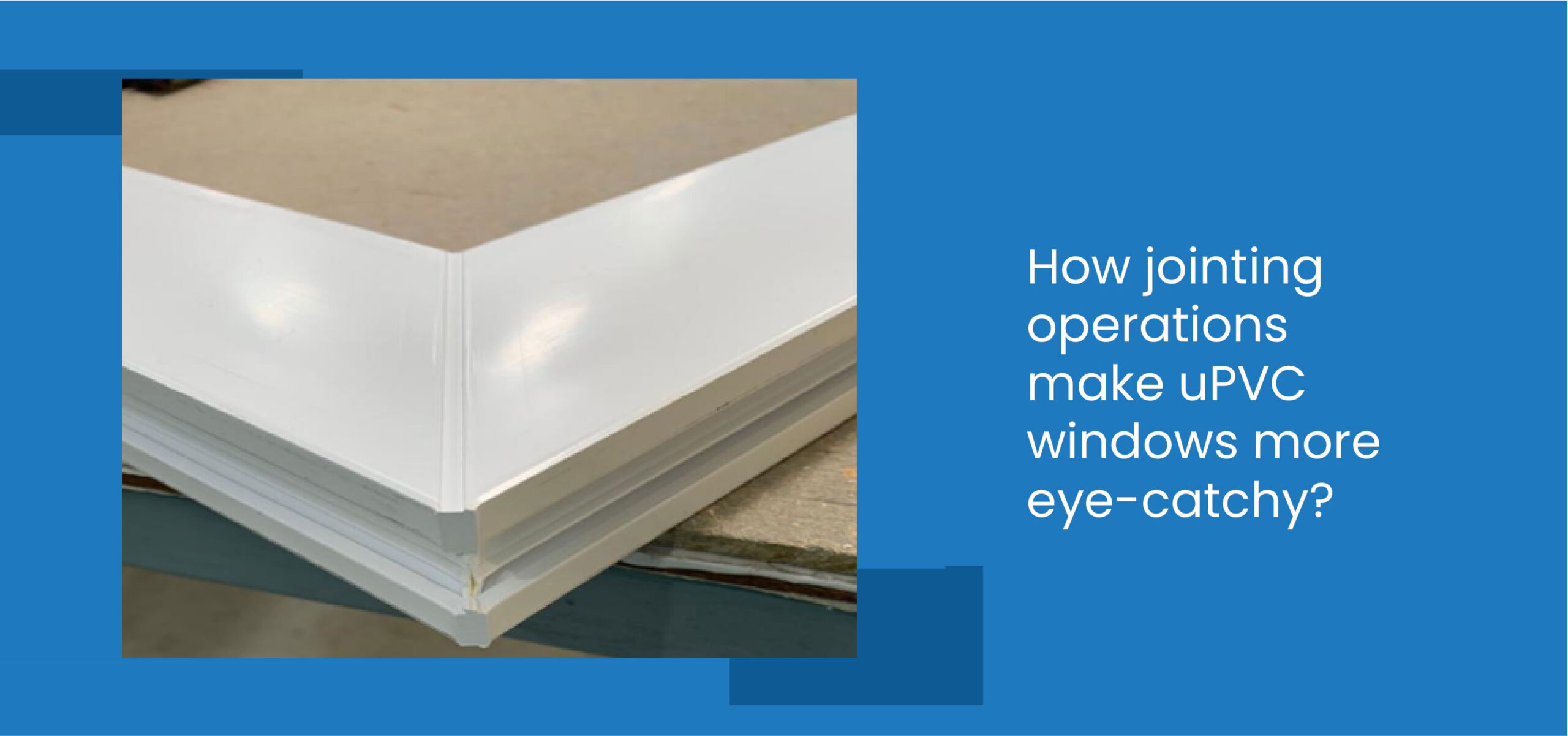

Corner Cleaning for Smooth Joints

A good weld joint will be with lip-shaped weld burrs, and weld burrs are cleaned with a corner cleaning machine.

CNC Corner cleaning machines have become very popular for handling large volumes. The conventional corner cleaning machines equipped with carbide tipped tools to handle smaller volumes by fabricators.

During the corner cleaning process, weld burrs are removed with a H-shaped grooving knife simultaneously at the top and bottom of the corner joint. This operation is known as feature grooving (3.5 mm width x 0.5 mm depth). The grooved area adds aesthetic look to the corners of the frame and sashes and make them more eye-catchy.

The cutters also chop-off the sharp external corners to facilitate easy insertion of the window frame into the aperture during installation.

Whether you are looking for a simple upgrade to the existing frame or cosmetic changes like a lick of paint, look for something more substantial and eye-catching. It not only improves the outdoor appeal but adds value to the property. There are few uPVC window hardware manufacturers in India who perform such precise operations.

A houselift with a joining operation for windows is a practical idea to explore. It is worth a long term investment. OBEN relies on the best product profile to deliver its promises. Talk to our experts about how you can serve the best to your customers.